Green for Generations

We are Green for Generations

We’re a family-run business. Sustainable thinking and reliability have been among our guiding principles for generations. This also applies to the concept of sustainability.

Our goal is clear: we want to reconcile social benefits, the environment and the economy in the best way possible thereby also protecting future generations. This is also what our motto 'Green for Generations' represents.

Our growth may be dynamic, but our attitude to sustainability is consistent.

We have chosen to focus on four core areas:

- We develop glass that reduces the energy consumption of buildings

- We produce our glass using ever less energy over time

- We do everything in our power to maintain a clean environment and to protect it

- We support our customers in constructing sustainable buildings

Innovations are the driving force behind our success. We acknowledge that we can only achieve this with motivated employees, who we support in achieving their goals, such as at our Glas Trösch Academy, for example, or within the context of our LIFT career programme.

Our action plan for carbon neutrality

2022

Our Scope

Current status

Scope 1

Direct emissions

Scope 2

Power consumption

Scope 3

Indirect emissions

START OF MEASURES

Green electricity

Converting electricity to renewable energy sources

FLOAT PROCESS

New technologies and use of electroboosting

Increase cullet percentage

Increasing cullet percentage at all float plants

Convert truck fleet

Converting trucks to alternative drives

Replace heating system

Replacing gas and oil heating systems with low-CO2 technologies

Replace company vehicles

Converting cars to alternative drives

Efficiency

Energy process optimisation at the production plants

2030

- 30%

Reduction scope 1+2

2050

« We intend to achieve net zero by 2050 »

We focus on sustainable products

We’ve been passionate about glass for over 100 years. Not only is it timeless in its beauty, it’s also incredibly eco-friendly. After all, glass is a natural product and its raw materials, such as quartz sand, soda and dolomite, are abundant resources.

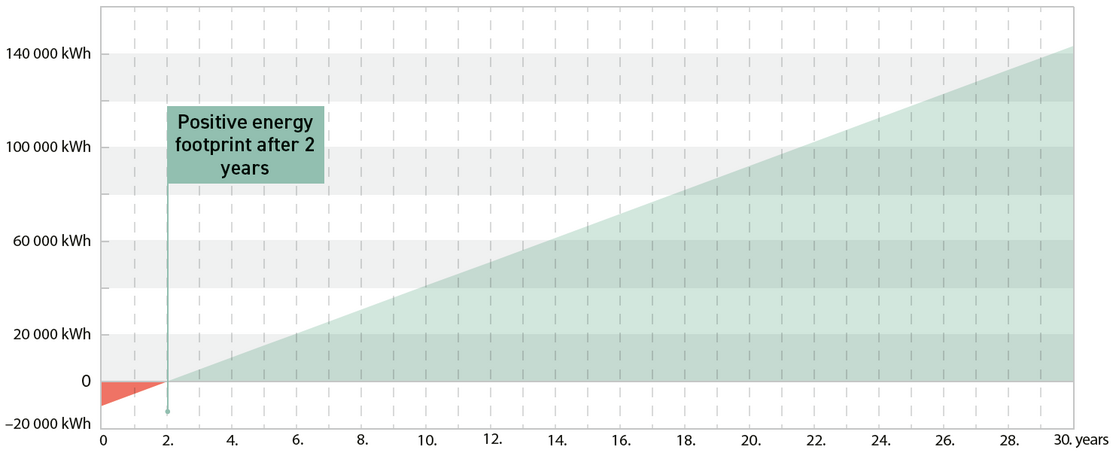

Manufacturing insulating glass requires a lot of energy. However, once installed in a building, its energy-saving potential is so high that it quickly pays for itself. Based on the average lifespan of around 30 years, the energy balance of our window and façade glass is clearly positive.

Our glass not only reduces energy consumption during the colder months of the year. At a time when hot spells are becoming more frequent, another important feature is its ability to provide heat protection in the summer. In this way, our solar protection glass ensures comfort indoors even when outside temperatures are high. It's also able to reduce, sometimes even completely eliminate the need for air conditioning systems.

With our special SILVERSTAR CONTROL glass, it’s even possible to remotely control sun exposure using a blind integrated into the gaps between the panes – thereby regulating energy and managing daylight as needed.

We’re not just focussed on glass solutions that reduce resource consumption – we also develop solutions that generate energy. The best example of this is our SWISSPANEL SOLAR, which brings colour to the otherwise rather dull design of solar panels. Using a special process, individually designed images can be printed on the front glass of the modules without having a significant impact on their effectiveness.

Our insulating glass saves huge amounts of energy – and therefore also reduces carbon emissions.

Based on an average life of around 30 years, the total energy footprint of our window and façade glass is significantly positive.

Saving with 30 m2 triple-glazed insulating glass: Ug value 0.6 W/m2K

Heating oil per year

570l

Heating oil after 30 years

17100l

kWh per year

5100kWh

kWh after 30 years

153000kWh

CO2 per year

1500kg

CO2 after 30 years

45000kg

Our products quickly start saving energy

We produce efficiently

Manufacturing flat glass is an energy-intensive process. That’s why we’ve been working to make it as efficient as possible for decades now. In our float glass plants, we use local raw materials to minimise hauling distances. Thanks to our patented system for reusing glass fragments, we also reduce the need for raw materials.

Around a quarter of the electricity used by our float glass plants is recovered energy

For all other types of energy, we opt for the most environmentally friendly combination possible to minimise our impact on the environment. We have also designed our melting furnaces in-house which has helped us ensure that our float glass factories are amongst the most efficient and environmentally friendly in the world.

We are audited and certified by independent institutes

Be it the international standards ISO 14001 (environmental management) or ISO 50001 (energy management), we voluntarily join initiatives by the Swiss Energy Agency and have pledged to continuously improve our CO2 emissions in line with our motto « Green for Generations ».

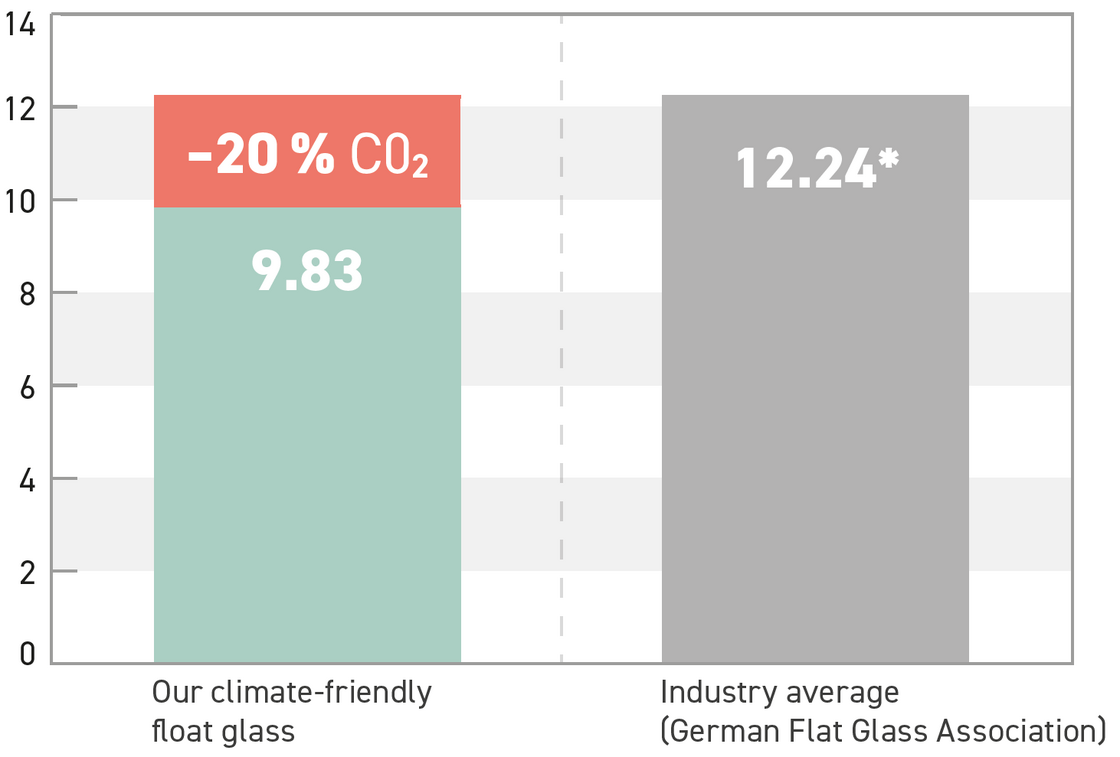

At Glas Trösch, the focus is on reducing CO2 emissions for the entire product range. According to current calculations, the standard glass we produce performs significantly better than the industry average.

According to the Environmental Product Declaration (EPD), the CO2 equivalent of our standard EUROFLOAT float glass with a thickness of four millimetres is merely 9.83 kg CO2eq/m2. The value is therefore almost 20 per cent (19.7%) lower than the 12.24 kg CO2eq/m2 from the model industry EPD of the German Flat Glass Association (declaration number: M-EPD-FEG-001000). Of course, the low value is achieved without compromising on quality, features or design.

The low CO2 equivalent was made possible by manufacturing processes that have been optimised over many years. In them, all available glass shards are fully put into the standard float glass and renewable energy sources are used. What’s more, we also utilise modern energy recovery processes. Thanks to the expertise of the highly qualified Glas Trösch production team, the efficiency of the specially developed melting furnaces has also been improved.

“It is important to us to achieve low CO2 values not just for individual product lines, but for the entire range.”

The advantages of our climate-friendly float glass

The lower the CO2 emissions, the better for the environment. Our entire range is produced in a climate-friendly way, resulting in a correspondingly high global effect. And there are other points that make float glass from Glas Trösch a good choice.

“Our climate-friendly float glass makes a significant contribution to reducing CO2 emissions and is suitable for all building typologies.”

Local shards

We fully utilise all available glass shards for our standard float glass in order to reduce the use of raw materials and process energy as much as possible. We do not need to transport broken glass between locations.

Eco-friendly logistics

Because we produce climatefriendly basic glass at all our production sites, our warehousing costs are low. In addition, the transport routes for the glass produced are reduced to the bare minimum.

We’re your partner for green buildings

Certification systems have been developed worldwide that allow for the sustainability of buildings to be ssessed and compared in order to promote climate-friendly construction.

Minergie, LEED, BREEAM, etc.

Whether it’s Switzerland's Minergie Standard, Germany's Sustainable Building Certificate (Gütesiegel Nachhaltiges Bauen), the US's LEED or the oldest and most well-known of them all - the UK's BREEAM certificate, each system has its own set of criteria with environmental, economic and social considerations, which are weighted differently and relate back to national regulations.

We help architects, planners and building owners achieve the best result for their preferred certification system with our glass solutions.

The individual footprint of construction products plays a major role in all systems. Environmental Product Declarations (EPD), which we provide for our basic glass options, form the basis for calculating ecological sustainability.

We protect our environment

Specifically, this means that we do as much as we can to avoid waste in all areas and recycle it wherever we can.

For us, environmental protection also means keeping emissions to an absolute minimum. Electric filters allow us to reduce the emissions of particulate matter and sulphur dioxide from our float glass plants, keeping them below the statutory requirements. In addition, we have been purifying production waste gases with the help of DeNOx systems for years.

We’re also constantly improving our ecological footprint in logistics. Our own truck fleet only uses vehicles with economical engines and the latest exhaust filters. Since 2021, we have also been switching to tractors that run on environmentally friendly fuels.

Last but not least, our product innovations also focus on the environment. Take BIRD PROTECT, for example – we developed this special glass together with the Swiss Ornithological Institute in Sempach to effectively prevent birds from colliding with windows. And our SILVERSTAR BIOELECTRIC is a solution tartgetting the growing number of electrosensitive people, by providing reliable protection against excessive external radiation.

More on the topic of sustainability

We make climate-friendly float glass the standard

Example calculation: our highly sustainable glass

Euroglas now using environmentally friendly separating agent

Glas Trösch and SANCO at BAU 2023 – Unveiling of a sustainable trade fair concept

Explanatory film on photovoltaics: Generating a lot of energy beautifully

We are a new exhibition partner in the Umwelt Arena

Glas Trösch Rail awarded "silver" by EcoVadis

| SWISSPANEL SOLAR

The customisable printed front glass for solar modules

CO2-neutral website

Partner of the Energy Agency of the Swiss Private Sector (EnAW)

Glass solutions for buildings that meet the Minergie construction standard